JP-8 Pipeline Replacement - Charleston, SC

Pond performed this design-build, fast track project to relocate a section of 8” JP-8 fuel transfer line from DFSP Charleston to Charleston Air Force Base (AFB), which was 8 miles long. The section was directly under Interstate 26 (I-26), an active 8-lane freeway. Pond’s engineers finished a work plan and design within a month, and construction began shortly thereafter.

Work included the installation of new fuel piping outside the limits of the new Remount Road overpass, draining and gas freeing the existing line, tie-in connections between new and existing, testing and flushing, and proper abandonment of the existing piping section under I-26. Work was performed in phases to allow continuous operation of the pipeline until draining for the tie-in. Phasing was coordinated with DFSP and Charleston AFB. The operational capability of the existing line could not be disrupted for more than seven consecutive days.

Project included the following:

- Clearing, grubbing and erosion control.

- Installation of dewatering wells and equipment.

- Shoring and excavation of Microtunnel and jacking and receiving pits.

- Microtunnel and jacking of a 24” casing pipe under I-26.

- Fabrication and installation of 8” carrier pipe for section located within casing under I-26.

- Radiographic inspection and weld testing (pneumatic test) for piping section located within casing.

- Installation of casing end seals and wax fill (flowable) interstitial space.

- Fabrication of carrier pipe from casing seals to tie-in points on east and west side of I-26.

- Radiographic inspection of welds.

- Construction of isolation valve pit and low point drain pit, and installation of associated valves and piping.

- Pneumatic testing and cleaning (pigging) of new piping section (prior to tie-in).

- Draining and pigging of existing piping system to remove fuel and vapor free piping section prior to cutting piping.

- Cutting existing pipeline and performing tie-in connections.

- Start-up and flushing of transfer pipeline.

- Removal of approximately 200 LF of piping between tie-in points and I-26.

- Pipe section under I-26 to be abandoned with ends filled with grout.

- Site cleanup and demobilization.

Related Projects

Related News

Pond celebrates safety accomplishments during project

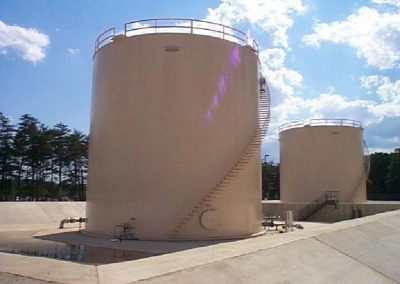

The Pond constructors team recently celebrated its safety accomplishments while working on two new 37,000 bbl jet fuel storage tanks. Since the start of field efforts, the Pond team has worked 9,617 man-hours on the project without experiencing any injuries. While the...

Pond announces new officers and executive leadership

A new group of leaders were recently recognized and promoted at Pond, a progressive, full-service architecture, engineering, planning and construction firm providing quality services to government, corporate and private sector clients throughout the world. These...

Pond provides quick response to BWI cargo tank farm repairs

Pond recently performed an emergency response to reactivate a moth ball fuel system at Baltimore/ Washington International Thurgood Marshall Airport (BWI Marshall) for a new cargo carrier at its midfield facility. Pond performed quick turnaround as a REG system needed...